A Visit to the Cigar Factory: The Art and Craft of Handmade Cigars

A cigar is not just a consumer product, but a delicate craftsmanship, with countless artisans behind it, working tirelessly with vast experience. Today, we take you on a journey through a traditional cigar factory, exploring the entire process of handmade cigar creation. Whether you are a cigar enthusiast or simply interested in craftsmanship, here you will witness the meticulous craft and feel the passion that goes into every cigar.

1. Cigar Ingredients: Select Tobacco Leaves

The first and most crucial step in cigar making is choosing the right tobacco leaves. Each tobacco leaf is carefully selected, and only the highest quality leaves make it to the production process. The tobacco farmers meticulously grow and harvest these leaves each year, ensuring their quality and aroma. These leaves are then sent to the factory for further processing.

2. The Cigar Workers: The Soul of the Craft

The heart of cigar making lies in the hands of the artisans. Each worker plays a vital role, from trimming the tobacco leaves to rolling and packaging, ensuring that every step is done with precision. The experience and skills of the workers directly impact the quality of the cigar. Through years of training and practice, they learn to control the cigar's density and smoke flow, providing the perfect smoking experience for every cigar lover.

3. Hand Rolling: A Combination of Art and Precision

Hand rolling is the most artistic part of cigar making. The workers carefully roll the tobacco leaves into a tight cigar shape, ensuring that each cigar provides smooth smoke and an excellent flavor. This process requires great concentration and skill, as even a slight mistake can affect the cigar's quality. Therefore, the workers dedicate a lot of time and effort to this step, ensuring every cigar meets the highest standards.

4. Final Inspection and Packaging

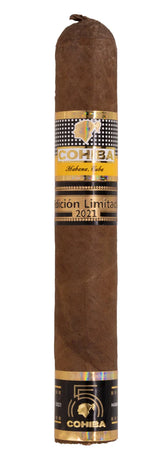

Once the cigars are rolled, they undergo a rigorous quality inspection. The factory's quality control team ensures that each cigar meets strict standards. Once approved, the cigars are beautifully packaged and ready to be sent to the market to meet cigar enthusiasts around the world.

5. Conclusion: A Fusion of Tradition and Innovation

In this factory, traditional craftsmanship and modern technology come together, driving the high-quality development of cigars. Whether it’s the selection of tobacco leaves or the rolling techniques, every worker invests significant effort into every detail. It is this dedication to quality that makes every cigar a fine piece of art, worthy of being cherished and savored.

By understanding the production process at the cigar factory, we gain even more admiration for the craftsmanship behind it. Every cigar is the result of the artisans' hard work, carrying the legacy of tradition and the brilliance of innovation. Whether you're new to cigars or a seasoned aficionado, you can taste the unique artistry in every cigar.