The Craftsmanship of Cuban Cigars: An Art Form

Cuban cigars are renowned worldwide for their exceptional quality and unique flavors, all of which stem from the exquisite craftsmanship behind their production. The process of making a cigar is not just a manufacturing task; it is an art form that integrates history, culture, and fine techniques. This article takes you on a journey to explore the meticulous craftsmanship of Cuban cigars, uncovering every detail of the process and experiencing the dedication that goes into each cigar.

1. Tobacco Cultivation: The Foundation of Quality

The quality of Cuban cigars starts with the cultivation of the tobacco. Cuba's climate and soil provide perfect conditions for growing premium tobacco. The tobacco-growing regions in Cuba, such as Vuelta Abajo and Pinar del Río, are famous for their rich, fertile soils and abundant sunshine, making them ideal for cultivating high-quality cigar tobacco.

Each leaf of tobacco is carefully cultivated, trimmed, and harvested by expert farmers. To ensure the best flavor, the tobacco is hand-selected multiple times, ensuring consistent quality across the leaves. The unique aroma and flavor of Cuban cigars are attributed to both the exceptional climate and the meticulous cultivation techniques used.

2. Tobacco Fermentation and Drying: Enhancing Flavor

Once harvested, the tobacco is sent to specialized fermentation rooms for fermentation. This process is one of the most critical steps in the cigar-making journey. Through fermentation, the chemical components of the tobacco change, reducing bitterness and enhancing its sweetness and aroma.

The fermentation process is carefully controlled, maintaining the right temperature and humidity to ensure the tobacco achieves its ideal flavor. This process lasts for several months and requires expert knowledge and experience to ensure the consistency and quality of each batch. After fermentation, the tobacco is sent to drying rooms to further reduce moisture content for use in the next stages.

3. Hand-Rolling: The Fine Craftsmanship

One of the most captivating aspects of Cuban cigars is the traditional hand-rolling process. While modern machines can mass-produce cigars, Cuban cigars continue to rely on handcrafted techniques, which sets them apart from other brands.

Hand-rolling cigars is a complex and time-consuming process, typically carried out by experienced torcedores (cigar rollers). The roller carefully selects the best parts of the tobacco leaves and layers them together before rolling them into a cigar. This process requires patience, precision, and skill to ensure that each cigar has an even tobacco density, smooth draw, and balanced flavor.

During the rolling process, the appearance and structure of the cigar are equally important. The roller must ensure the surface of the cigar is smooth and even, ensuring the cigar burns evenly and is easy to light. Every detail reflects the craftsmanship and respect for traditional techniques.

4. Final Touches and Packaging: The Finishing Details

Once the cigars are rolled, they undergo a final trimming to ensure the tobacco is perfectly aligned and the draw is balanced. The cigars are also carefully inspected to meet the high standards of quality.

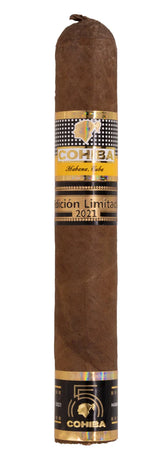

After the final touches, the cigars are placed into specially designed boxes for packaging. These boxes, often made from premium wood, not only protect the cigars but also provide an elegant presentation. Cuban cigars are often sealed with unique labels and stamps, signifying their luxury and high-end status.

5. Aging: Enhancing the Flavor

After the cigars are rolled and packaged, they undergo a period of aging. This aging process, which can last several months or even years, allows the cigars to mature and develop a more refined and complex flavor profile. Aging helps the chemical components in the tobacco blend together, making the flavor smoother and more rounded.

The aging process is crucial to the flavor profile of Cuban cigars. Only with proper aging can the cigars reach their full potential in terms of taste and aroma. This step also relies on expert storage conditions and management, ensuring the cigars age in ideal conditions.

6. Conclusion: The Art and Legacy of Cuban Cigars

The craftsmanship behind Cuban cigars is a sophisticated art that integrates tradition, skill, and innovation. From the cultivation of tobacco to fermentation, hand-rolling, packaging, and aging, every step requires high levels of expertise and attention to detail. This is what makes Cuban cigars some of the most revered luxury items in the world.

This art form is not just about the pursuit of cigar quality; it is also about the legacy and respect for Cuban culture. Every Cuban cigar is a tribute to the craftsmanship, tradition, and history of Cuba, offering an experience that transcends time.